Filtration VanAir

Série F200 VanAir

Compressed Air and Gas Filters

FEATURES

Heavy duty cast aluminum housings

Maximum working pressure 250 PSIG

Nine filtration grades

Push on filter elements

BENEFITS OF THE F200 SERIES

Rugged construction

Low maintenance

Easy to service

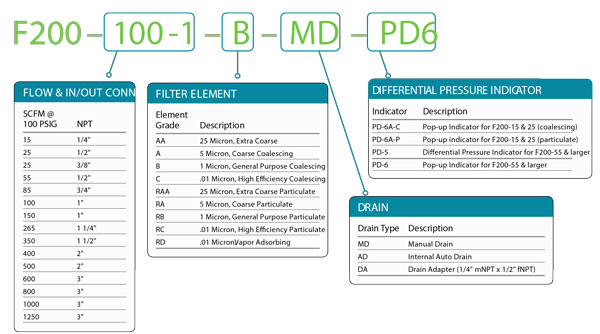

F200 Series filter selection

How to select a filter

Determine the flow rate and pressure at the point in the air system where the filter is to be installed.

Select the filter model with a flow rating equal to or exceeding the operating requirement. For filter flow ratings at pressures other than 100 PSIG, consult the table on the next page or contact Van Air Systems

Choose the filter element letter grade that meets the purity level required by the application.

Select a drain type.

Select a differential pressure indicator.

Clean, trouble-free compressed air and gas

Rugged housings and long-lasting elements give you the best value for your money.

They’ll provide dependable filtration to reduce your downtime, maintenance and operating costs.

Van Air F200 series filters are currently providing these benefits in a wide range of applications:

Instrument air & gas

Pre-filter and after-filter for deliquescent & regenerative dryers and refrigerated dryers

Pneumatic hand tools

Abrasive blasting

Dust collectors

Air cylinders

Air Motors

Blow molding

The F200 Series from Van Air Systems

Compressed air is a vital utility in many industries. Yet contamination plagues many air systems. Compressor lubricants and oil aerosols. Dust. Dirt. Scale. These damaging contaminants lead to lost productivity and increased down time. It doesn’t have to be this way. Turn to F200 Series filters. The toughest most reliable industrial filters for compressed air and other gases.

Simple is better.

Each F200 filter includes a rugged cast aluminum housing and a filter element constructed with stainless steel support cores and high performance filter media. A filter element comes pre-installed in every housing. Van Air Systems’ filter elements are easy to install. Simply push the element into place for a snug fit. Unlike competitive filters, F200 filters use no awkward tie rods or fasteners.

How it works.

Simple operation is key. Compressed air or gas enters the inlet side of the head and passes through the single filter element. In oil removal applications, air or gas flows from the inside to the outside of the element. In particulate removal applications the flow pattern is from the outside of the element to the inside. Clean air or gas exits the opposite side of the head.

Application versatility.

The F200 Series includes housings with connection sizes from ¼” to 3” NPT for flow rates from 15 to 1250 SCFM (at 100 PSIG) and nine filtration grades to meet your exact system requirements. All F200 series filters have a maximum working pressure of 250 PSIG. F200 filters are approved for the use with both compressed air and hydrocarbon gases.

F200 Series accessories

Rugged design, durable construction

Strength and durability matter. That’s why every F200 filter is designed and constructed with the industrial compressed air user in mind.

Filter application guide & suggested installation

STANDARD EQUIPMENT

Cast aluminum housing

Maximum working pressure: 250 PSIG (17.2 BARG)

Interior epoxy coating

Exterior epoxy coating and epoxy powder coat finish

Manual ball valve

Pop-up differential pressure indicator

O-ring seals

Inlet/outlet – NPT

Push on element

Initial element included

OPTIONAL EQUIPMENT

Cast aluminum housing

Maximum working pressure: 250 PSIG (17.2 BARG)

Interior epoxy coating

Exterior epoxy coating and epoxy powder coat finish

Manual ball valve

Pop-up differential pressure indicator

O-ring seals

Inlet/outlet – NPT

Push on element

Initial element included